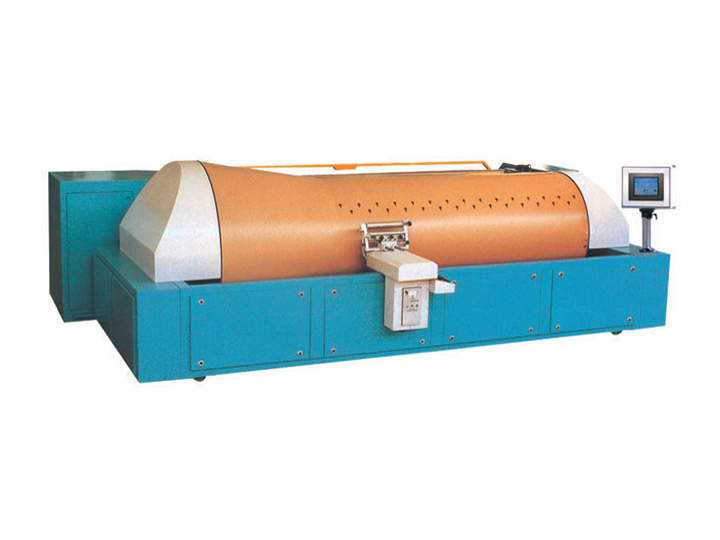

Automatic Sectional Warping Machine Series

Technical Features

1. Warping and beaming is driven by A.C.frequency converter so that constant yarn speed and tension is gained even at high speed.

2. The special machinery-electricity-gas integrated oil pressure equipment can create oil pressure and drive the clamping breaker to realize the controlling of warp break, The proportioning valve contro the damping mode of the outer steel node and realize the automatic control of the beam tension.

3. Warp servo transmission uses the ball bearing lead screw structure and has the characteristic of rapid response, high precision. Bar position setting and initial, potential adjustment will complete automatically once button pressing.

4. The forward and backward movement of warping table is controlled by AC digital servo controller and transmission of ball screw rod. The system is also equipped with press roller and several kinds of sensors.

5. The warping table will be backed for the same distance in the warping procedure.

6. Serve motor will measure the thickness of warp thread for several times through the transmission of the ball bearing lead screw and realize the automatic measurement of the warping displacement. The application of press roller to keep the flatness of the thread.

7. The steel drum with fixed cone is precisely checked on inertial balance.

8. Mechatronics and automation is realized with a bus PLCs digital A.C. servo controllers microcomputers with TTS (touching sensor screen) and one long-distance monitor.

9. The warping frame is moved on the rail, but the lease reed and creel is fixed so that the position of warp stripe is unchanged and the side yarn tension is also constant.

10. The movable beaming part can match one or more warping machine. The electrical source and air supply are connected by the inserter, simple and reliable.

11. Various types of bobbin creel are provided, and according to the customer’s request, spindle number and space are optional.

12. Several types of tension devices and stop motions are provided.

13. Static eliminator is provided in the warping table and oiling equipment in the beaming part.

1. Warping and beaming is driven by A.C.frequency converter so that constant yarn speed and tension is gained even at high speed.

2. The special machinery-electricity-gas integrated oil pressure equipment can create oil pressure and drive the clamping breaker to realize the controlling of warp break, The proportioning valve contro the damping mode of the outer steel node and realize the automatic control of the beam tension.

3. Warp servo transmission uses the ball bearing lead screw structure and has the characteristic of rapid response, high precision. Bar position setting and initial, potential adjustment will complete automatically once button pressing.

4. The forward and backward movement of warping table is controlled by AC digital servo controller and transmission of ball screw rod. The system is also equipped with press roller and several kinds of sensors.

5. The warping table will be backed for the same distance in the warping procedure.

6. Serve motor will measure the thickness of warp thread for several times through the transmission of the ball bearing lead screw and realize the automatic measurement of the warping displacement. The application of press roller to keep the flatness of the thread.

7. The steel drum with fixed cone is precisely checked on inertial balance.

8. Mechatronics and automation is realized with a bus PLCs digital A.C. servo controllers microcomputers with TTS (touching sensor screen) and one long-distance monitor.

9. The warping frame is moved on the rail, but the lease reed and creel is fixed so that the position of warp stripe is unchanged and the side yarn tension is also constant.

10. The movable beaming part can match one or more warping machine. The electrical source and air supply are connected by the inserter, simple and reliable.

11. Various types of bobbin creel are provided, and according to the customer’s request, spindle number and space are optional.

12. Several types of tension devices and stop motions are provided.

13. Static eliminator is provided in the warping table and oiling equipment in the beaming part.

Main specifications

| Model | Automatic series | ZY4600 | ZY4800 |

| Work width | 2300 ~ 4600(mm) | 2300~4800mm | |

| Beam flange diameter | 800、1000、1250(mm) | 800、1000、1250mm | |

| Warping speed | 0 ~ 800(m/min) | 0 ~ 600(m/min) | |

| Beaming speed | 0 ~ 200(m/min) | 0 ~ 100(m/min) | |

| Deviation of Beaming tension | ≤ ±2% | ≤ ±2% | |

| Braking distance | ≤ 3(m)(500m/min) | ≤ 2(m)(300m/min) | |

| Beaming tension | ≤ 8000N | ≤ 6000N | |

| Drum diameter | 1026(mm) | 1026(mm) | |

| Cone Length | 1010、1360mm | 1010mm | |

| Stripe traverse speed | 0.001 ~ 9.999(mm/r)(stepless) | 0.001 ~ 9.999(mm/r)(stepless) | |

| Stripe width | 0.1 ~ 400.0mm | 0.1-999.9mm | |

| Spindle space |

250x250(mm)(wool yarn ,cotton yarn, blended yarn) 290x290(synthetic filament) |

250x250(mm)、280x280(mm) | |

| Input voltage | 3x380V(±10%) | 3x380V(±10%) | |

| Capacity | 40KVA 50KVA | 30KVA | |

| Warping motor power | 11KW 、 15KW | 7.5KW | |

| Beaming motor power | 15KW 、 22KW | 15KW | |

| Warping and beaming frame weight | 5500(kg) | 4500(kg) | |

| Creel weight | 2500(kg) | 2500(kg) |